How to Make an Artificial Muscle Out of Fishing Line

You’ll need fiber, some weights, a motor, and a heat gun to get you started.

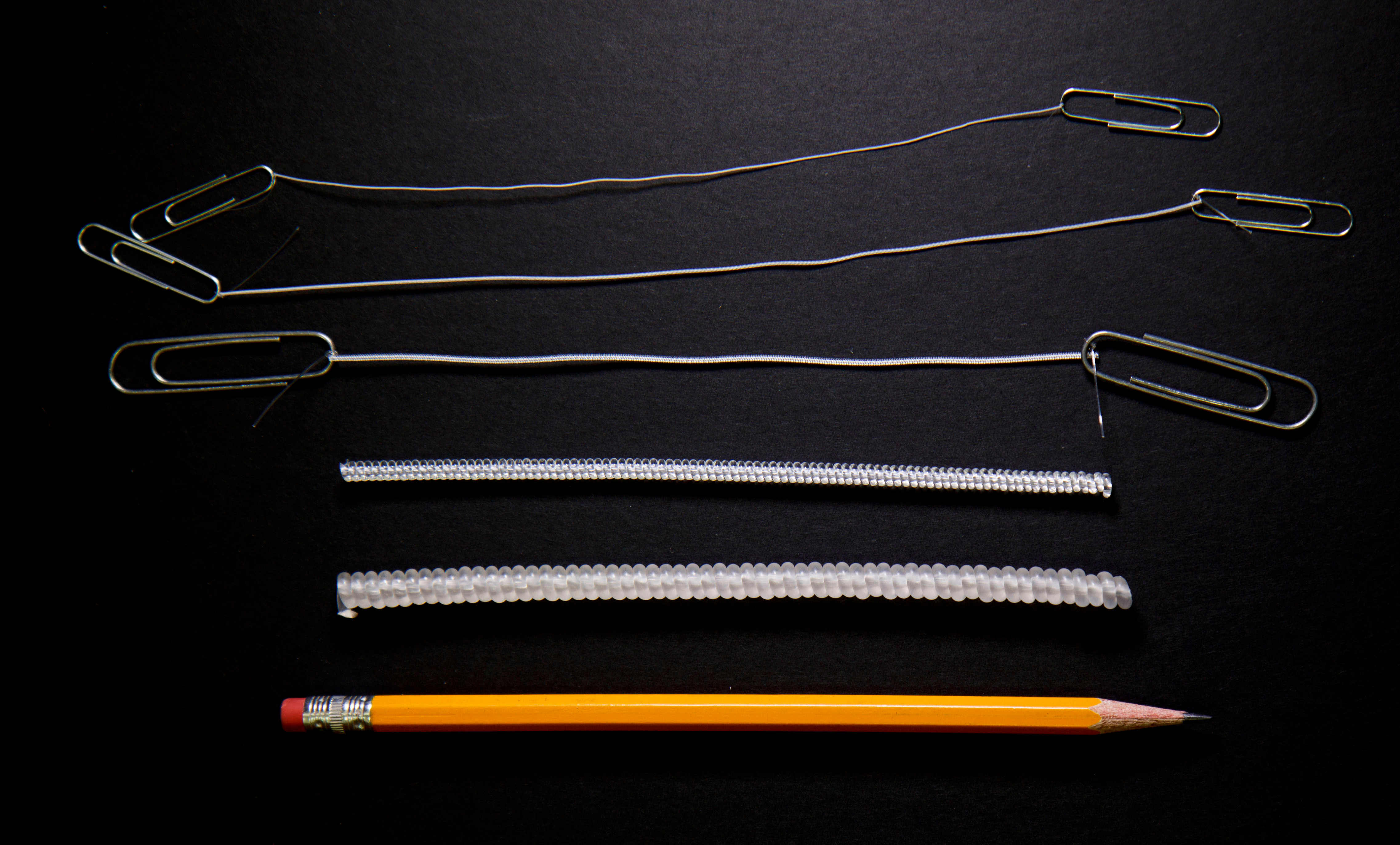

University of Texas at Dallas researchers and their international collaborators have made artificial muscles in a variety of sizes from ordinary polymer fishing line. Credit: University of Texas at Dallas

A couple of weeks ago, SciFri aired a segment about researchers who created artificial muscles using fishing line and sewing thread. Several of you expressed interest in learning more about how to do it, so we asked Carter S. Haines, lead author of the study about the process, to write us a guide. Here it is:

First, you need some fiber. Any nylon monofilament line can work, but something in the 2-20 pound test range is good starting material.

Next, you’ll need something to twist your fiber. For thin, lightweight fishing lines, a simple hobby motor with a hook attached will do the trick. For heavier-duty line you may need to find something beefier like a power drill. (If you go this route, please make sure you take proper safety precautions, especially because the line can accidentally snap in half during twisting.) Cut a length of fishing line and attach the top end to the motor.

Hang a weight on the bottom end of the fiber to keep it under constant tension while you twist it. This may take some trial and error: If the weight is too heavy, the fiber can break during twisting, but if it’s too light, the fiber will just twist up into a messy tangle of plastic instead of a nice clean coil. As a general rule of thumb, multiplying the fishing line’s pound test rating by about 11 or 12 will give an estimate of the number of grams necessary (for instance, 20 pound test fishing line coils well at approximately 230 grams, or about half a pound).

Once the weight is attached, you also need to prevent the end attached to the weight from rotating while you twist from the top. Be creative here—all you need is some way to let the weight move up/down freely without rotating. (We often tie both ends of the fishing line to paperclips and use those to hang the line on the motor and to hang weights on the line. If you do this, you can put a rod, such as a bamboo skewer, through the lower paperclip to hold it from rotating.) Then, turn on the motor and start twisting the filament. Be patient and don’t go too fast. If you have the right weight, soon enough the line should start to coil. Continue twisting until the entire line is coiled.

At this point, the muscle is very tense. The coils are squished up against one another, and there’s no room for the muscle to contract. One way to solve this is to increase the weight on the muscle. In general, adding another 50-100 percent of the weight used for coiling works well (so, for the 20 pound test fishing line coiled at 230 grams, you can try increasing the load to approximately 400 grams, or 0.88 pounds). Another option is to set the motor in reverse and untwist the muscle slightly. But don’t go so far that the coils start to pull out to a straight line again when you heat it in the next step!

Once the muscle is ready, it’s time to heat it. A heat gun works well—just make sure not to overheat it (it’s best to stay below 150â°C or 300â°F). You will run through several cycles of heating and cooling. (Heating and cooling times depends on the diameter of the line and the temperature of the heat gun.) For the first few cycles, the muscle will actually elongate, not contract. Surprisingly, this is a good thing! We call it “training,” and it’s necessary to make even more room between the coils and to stabilize the muscle. Once trained, when you heat the muscle again, it should contract and lift the weight. When you let the muscle cool, it will relax back to its starting point. Congrats, you’ve just made your first fishing line artificial muscle!

Tip: Although it doesn’t lift as much weight, smaller, lightweight fishing line (try 4 pound test or lower) can heat up and cool down more quickly, making for an impressive, fast-responding muscle.

Tip: It is possible to find silver-coated, multifilament nylon sewing thread for sale online. This material can be twisted into a coiled muscle that contracts when electrically heated by an adjustable power supply. (Always use appropriate safety precautions when working with electricity.)

Tip: Without precise control, it is hard to get very high stroke (the amount of its original length by which the muscle contracts), but a 10 percent contraction in length is a good point to shoot for.

Carter S. Haines is the lead author of “Artificial Muscles from Fishing Line and Sewing Thread” (Science). He is pursuing a Ph.D. in materials science and engineering at the University of Texas at Dallas.