The Flight of the RoboBees

08:04 minutes

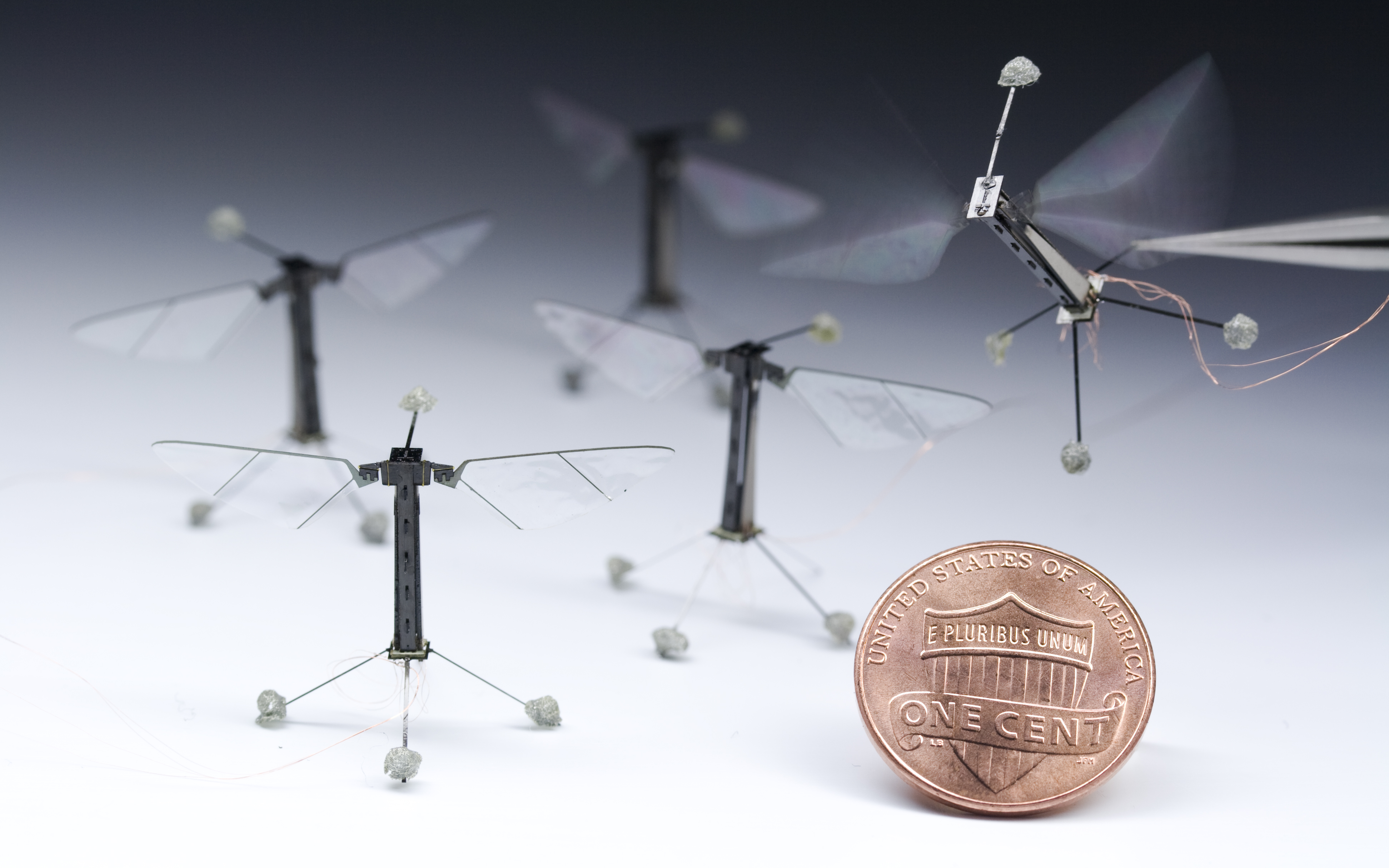

A group of Harvard scientists have a vision: to build a tiny robot that can fly, work together in groups, and even pollinate flowers like a honeybee. Meet RoboBee, whose latest feat was published in Science. The 80-milligram robot can fly to a surface, perch on it using electrostatic forces, and gently take off from that surface — saving valuable energy in the process.

E. Farrell Helbling, a Ph.D. candidate in the John A. Paulson School of Engineering and Applied Sciences at Harvard University, was the lead researcher on the RoboBee project.

“They are very cute,” Helbling says of the tiny robots. “They weigh about 80 milligrams, so it takes about 30 of them to weigh a penny.”

The RoboBees have tiny bodies and wings that flap at approximately the same frequency as a bumblebee’s wings.

“The inspiration was really looking at nature and bees,” Helbling says. “Bees are fast and agile insects that are able to perform quick aggressive maneuvers. They can fly through cluttered dynamic environments and they can work both as an individual as well as in a collective. So you could imagine having one collective group task but then each individual also needs to be able to carry out its individual mission staying in the air, flying controlable, sensing the environment and carrying a load. And there was really no robotic or mechanical equivalent that had that biological complexity at that scale and so it’s just a really rich area of engineering to explore.”

A group of robots like RoboBees could be invaluable in search and rescue missions or for forming impromptu communication networks. Tiny, swarming robots could also help pollinate crops.

The RoboBees still need a lot of work, however. The current versions are still attached to a power source with tiny wires. Perching helps them conserve energy, but Helbling eventually wants them to have their own power supplies, and to be able to sense their environment.

“Our main focus is trying to get onboard sensing so that they can sense their environment and sense their own state — an onboard brain so that they can, you know, update their control parameters and stay in the air, muscle drivers to make sure that the actuators are moving correctly and then, of course, most importantly is a power supply,” Helbling says.

—Elizabeth Shockman (originally published on PRI.org)

Below, researchers Robert Wood and Moritz Graule discuss the benefits of perching, and how they developed a robot that achieves this energy-saving feat.

Credit: Carla Schaffer/AAAS

E. Farrell Helbling is a Ph.D. candidate in the John A. Paulson School of Engineering and Applied Sciences, at Harvard University in Cambridge, Massachusetts.

IRA FLATOW: Next up, imagine a group of honeybees hard at work gathering pollen in a field, flying from flower to flower, communicating to each other about where to find the best food. That’s always helpful, and it’s helpful to bring in the pollinating plants that they visit in the process bringing all that pollen in. Now imagine that the days doing this work are robots.

That’s the vision driving the RoboBees project. It’s a years-long effort to build tiny, flying, swarming robots that could help pollinate crops or aid in rescue and beyond. The group’s latest milestone is published in Science this week. And the bees can now perch on glass or wood or even natural leaves. And you can see a video of the robots on our website at sciencefriday.com/robobees.

We’re talking about the flight and more of the RoboBees with my guest, Farrell Helbling is a Ph.D. candidate at Harvard School of Engineering and Applied Sciences, and lead researcher on the RoboBees project. Welcome to Science Friday, Farrell.

FARRELL HELBLING: Thank you. It’s good to be here. I’m excited.

IRA FLATOW: Thay’re cute little robots. Describe them to our listeners.

FARRELL HELBLING: They’re very cute. It is a centimeter-scale, biologically-inspired flapping wing aerial vehicle. They weigh about 80 milligrams, so it takes about 30 of them to weigh a penny. It’s a carbon fiber airframe with two piezoelectric actuators on the side, and they independently actuate the wings on the left and the right. And those create asymmetric body torques, which allow us to control flight.

IRA FLATOW: Described perfectly like an engineer, I want to compliment you.

FARRELL HELBLING: Sorry about this.

IRA FLATOW: Does it fly like a bee? Is the same wing action on the little RoboBees?

FARRELL HELBLING: It’s very similar. So it uses similar amounts of power, and it flaps at similar frequencies to bees and flies or similarly sized insects. But its center of mass is well below the wings, so its body axes are slightly different than an actual honeybee.

IRA FLATOW: So what was the inspiration for the project? Why do we need tiny flying robots that work together like bees?

FARRELL HELBLING: I think that the inspiration was really looking at nature and bees. Bees are fast and agile insects that are able to perform quick, aggressive maneuvers. They can fly through cluttered, dynamic environments. And they can work both as an individual as well as in a collective. So you could imagine having one collective group task.

But then each individual also needs to be able to carry out its individual mission of staying in the air, flying controllably, sensing the environment, and carrying a load. And there was really no robotic or mechanical equivalent that had that biological complexity at that scale. And so it’s just a really rich area of engineering to explore.

IRA FLATOW: In fact, it gives you a platform to study how to actually create new kinds of materials and how to work with them.

FARRELL HELBLING: No, it definitely does. I think that one of a very interesting things that has come out of this project and that we’re excited about the technology is how to manufacture at the centimeter scale. So a few decades ago, MEMS technologies had really taken off and so there was a good example of how to manufacture at the microscale. And then we’ve had larger machining technologies for a long period of time, but centimeter-scale manufacturing has been really difficult.

And so we’ve come up with a process called smart composite microstructures, which is a way to design mechanical linkages in a flat sheet. And that has allowed us to mass produce many different types of centimeter-scale robots, like the RoboBee, like the Harvard ambulatory microrobot, and other things as well.

IRA FLATOW: Talking with Farrell Helbling of School of Engineering at Harvard on Science Friday from PRI, Public Radio International. And as I understand, it’s constructed– when you fashion it, it’s like one of these pop up books that sort of pops up as it’s being made and forms the RoboBee.

FARRELL HELBLING: Yes, that is true. So the one that is in the paper is actually– some of the linkages are folded by hands, the transmission system that connects the actuator to the wing. And other things are hand-assembled. But a lot of work did go into thinking about how we can put flat sheets together, laminate them, and then create scaffolding systems so that it would only take one push to get the entire structure to pop into its final shape. Because that would really speed along the process, to make a swarm of these.

IRA FLATOW: A swarm– I’m thinking Michael Crichton now. Prey– did you read the book Prey? I advise you to read the book [LAUGHS]. Because one of the things he did, one of the things that the little tiny flying robots did is they spoke and talked to each other. Are you trying to do that with the little mini robots, flying them?

FARRELL HELBLING: I think that is definitely one of the goals in the future. We haven’t really done it, because these robots are so small. They have such a light payload capacity that our main focus is trying to get onboard sensing so that they can sense their environment and sense their own state, onboard brain so they can update their control parameters and stay in the air, muscle drivers to make sure that the actuators are moving correctly. And then of course, most importantly, as a power supply.

IRA FLATOW: Because they’re still hooked up by a tiny little wire.

FARRELL HELBLING: They are. You can see it in all the videos that we’ve published. The actuator signals are still given through– those are actually four wires, four very thin wires that run to the actuators. These bees that we have now, they only have a payload capacity of about like 40 to 80 milligrams. So it’s not much room for a battery.

IRA FLATOW: Can they now perch on flowers and things like real bees? Have you taught them how to do that?

FARRELL HELBLING: Yeah, they can. And I think that that’s one of the great examples of why it’s so important to perch, is because we don’t have large power supplies on these centimeter-scale robots. And so it’s important to be able to pause flight while remaining aloft so that you can continue the mission while conserving energy. And so we’ve created these electrostatic adhesives that allow the robot to adhere to many different surfaces, like you mentioned– glass, wood, brick, natural plant structures. It’s really exciting.

IRA FLATOW: It does sound exciting. So what’s your next challenge coming up, next step you want to do?

FARRELL HELBLING: The next steps are definitely to integrate as much as we can onboard the body of the vehicle. So like I said, brain, muscle drivers, sensors, so that these bees can control their own flight without needing external computers, external motion capture arenas. Still powered for the time being until we can come up with a solution for lightweight power. But that’s a really big push. I think it would be really important to show that these bees can think and sense their environment on their own.

IRA FLATOW: That’s terrific. We wish you great luck. And thanks for coming on today. I have to buzz off right now.

FARRELL HELBLING: Thanks for having me. It’s been great to talk about.

IRA FLATOW: Couldn’t help myself. Farrell Helbling is a Ph.D. candidate in Harvard’s School of Engineering and Applied Sciences. And she’s the researcher for the RoboBees project. And as I say, go to our website at ScienceFriday.com/robobees and watch these. These are really cute little flying bees. You won’t think that they’re really unreal. That’s terrific.

Copyright © 2016 Science Friday Initiative. All rights reserved. Science Friday transcripts are produced on a tight deadline by 3Play Media. Fidelity to the original aired/published audio or video file might vary, and text might be updated or amended in the future. For the authoritative record of ScienceFriday’s programming, please visit the original aired/published recording. For terms of use and more information, visit our policies pages at http://www.sciencefriday.com/about/policies.

Christie Taylor was a producer for Science Friday. Her days involved diligent research, too many phone calls for an introvert, and asking scientists if they have any audio of that narwhal heartbeat.