Chemists Make A Coating That Can Slow A Golf Ball’s Roll

12:04 minutes

With spring here, the days are getting warmer and longer, meaning conditions are perfect for a trip to the golf course. And while golf is certainly a game of physics—force, angles, parabolas—this week researchers presented work showing that chemistry could play an important role on the golf course as well. Speaking at the meeting of the American Chemical Society in San Diego, researchers described a high performance coating that could be incorporated into the polyurethane shell of a golf ball.

The hydrophilic (water-loving) coating would make tiny bits of water stick to the surface of the golf ball and sheet off, modifying the way the ball interacts with the grass of the green. That interaction, says Tom Kennedy, owner of Chemical Innovative Solutions Inc., would lead to the ball rolling more slowly and reliably, especially on “fast,” closely-cut greens in dry and windy conditions.

Kennedy joins Host Ira Flatow to discuss the technology, and how hydrophilic coatings could find a home in other applications, including solar cells.

Keep up with the week’s essential science news headlines, plus stories that offer extra joy and awe.

Tom Kennedy is the owner of Chemical Innovative Solutions in Wilbraham, Massachusetts.

IRA FLATOW: This is Science Friday. I’m Ira Flatow. Later in the hour, how a stroke of luck helped scientists learn what lurks in the oceans under Antarctica’s ice sheets. But, first, now that baseball season has started, golf grabs the spotlight with the Masters Tournament just a few days away.

And while golf is certainly a game of physics, you’ve got your ball speed, your height, and your angle, there’s an old saying in golf. Drive for show but putt for dough. That means that the putting green is the ultimate test where games are won or lost.

And with 18 different greens, golfers are faced with 18 different ways the ball may travel, depending on whether the grass is slippery or soggy. It’s cut tall or short. But now science is here to help.

This week at the meeting of the American Chemical Society, researchers announced they have developed a coating for golf balls that would make them roll more consistently, more predictably, across all the putting surfaces, no matter how wet, how short the grass. Joining me now to talk about it is Tom Kennedy. He’s the owner of the company Chemical Innovative Solutions in Massachusetts. Welcome to Science Friday.

TOM KENNEDY: Thanks, Ira. Nice to be here.

IRA FLATOW: Did I get that– all those different ways, all those different factors that could affect a putt.

TOM KENNEDY: Absolutely. And, actually, there’s a few more. The problem today is that agronomy has gotten so good with a lot of the different grasses available and the mowing machines, that what happens is the greenskeepers cut the greens down very short. Typically, they’re an 1/8 of an inch so 0.125 inches. But like Oakmont in 2016, they went down to 0.09.

IRA FLATOW: Wow.

TOM KENNEDY: I know, very short. And that’s OK as long as the weather holds up. But when it gets very dry and very windy, those greens get very, very fast, as the term in golf is.

IRA FLATOW: So judging the way the ball rolls, that’s really part of the game on the putt there, right?

TOM KENNEDY: Absolutely. And the problem is when those greens get very, very fast, in my estimation, it becomes a game more of chance than a game of skill. And the player’s skill is not on display as much as you’d like to see it. I think you may have remembered, 1999 at Pinehurst No. 2 was the eighth hole. John Daly took an 11, and he took an 11 because he putted the ball up at the hole and it rolled back to him twice. And the second time, he was so frustrated, he hit a moving golf ball, which is a two-stroke penalty in golf, and, as a result, took an 11 on the hole.

IRA FLATOW: Yeah.

TOM KENNEDY: So not a great display of a golfer’s ability, more a display of the strange agronomy and strange process you see on some of these very fast greens.

IRA FLATOW: So how does your use of chemistry to make a coating, how does that help or determine the roll of the ball?

TOM KENNEDY: Well, that’s what I looked at. And I thought, gee, this should be better than it is. And a lot of the players get upset when they see these very, very fast greens. So the solution is a hydrophilic coating for golf balls.

Many times, people like to see hydrophobic because they think, oh, we want to resist the water that’s on golf courses or rain or what have you. But a hydrophilic coating is a water-loving coating, if you will, whereas a hydrophobic coating is a water-hating coating. So a hydrophilic, it tends to sheet out more on the surface of the golf ball. And as a result, it gives a truer roll and also will allow for the golf ball to be a little bit slower on these very, very fast greens and make the game again more a game of skill than of chance.

IRA FLATOW: So how much difference can this coating make on the success of a putt, putting the ball in the hole. Is there a percentage? Or does it work better by x number of putts?

TOM KENNEDY: So my initial testing of our coating showed that we were getting a difference, 8.25 for a retail ball, 8.25 feet, and 7.58 feet for the new hydrophilic coating. It doesn’t seem like a lot. But when there’s a million-dollar difference between first place and second place, that certainly does make a difference.

IRA FLATOW: I’ve heard some people say, why not just coat it in Teflon so that things don’t stick to it. You have the opposite idea, right?

TOM KENNEDY: Exactly. It’s the opposite idea. And I think that’s the counterintuitive part of it, is there’s a three-pronged attack that I’ve used to try and make these golf balls very different on these very fast greens. The first is an interpenetrating polymer network.

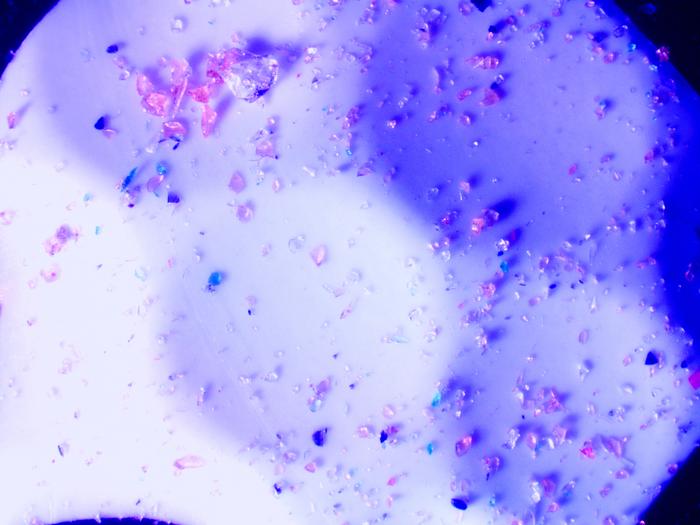

The second is an adsorbent or adsorbent material, like a molecular sieve. And the third is a super absorber polymer, like you see in diapers or other areas. You also see a lot of landscapers use it to hold water in yards.

IRA FLATOW: So what’s going on in the physics of the ball as it’s rolling with your hydrophilic coating on it? Let’s get into the weeds on this.

TOM KENNEDY: Literally, right, into the grass.

[LAUGHING]

Good one. Yeah, so what’s happening is that you’re getting this film on the surface of the ball of the water. And as a result, it has more of a synergistic effect with the grass and the green, as opposed to having the hydrophobic effect. So you’re getting the ball to, quote, unquote, “stick to the green better.” And that’s through the use of this interpenetrating polymer network, the adsorbent materials, and the super absorber polymers.

IRA FLATOW: So even if it’s really dry, it is getting some water sticking to it, which helps the roll.

TOM KENNEDY: Bingo. It slows the roll down. And so a lot of these courses, I’ll quote Zach Johnson for the 2018 US Open at Shinnecock. He said, “They’ve lost the course.”

It was the third day. It was a very dry day, very windy, and the conditions were just extremely difficult for putting, again, a game of chance versus a game of skill. So these new coatings will allow the ball to have a better interface with the green and will slow it down on some of these very, very fast greens.

A lot of these course designers build false fronts into the greens. So what that is, is it’s part of the fairway that comes up to the green. And if you don’t quite get it on the front of the green, the ball rolls back into the fairway, which is a nice thing for the designer. But if the greens are extremely fast, then you have the ball rolling off the green back into the fairway. And it’s, again, not a great test of golf in my estimation.

IRA FLATOW: So how easy is this to put on a golf ball? I mean, is it embedded in the coating or the shell on the ball or is it sitting as a layer? How does it work here?

TOM KENNEDY: Well, that’s a great question. And, typically, the golf balls of today have a two-part polyurethane as the coatings. And the reason for that is it’s a very durable coating. So you’re striking this golf ball at ungodly amount of pressure with the golf club.

The grooves on the club cut into the surface, and the polyurethane coatings are able to withstand that. The polyurethane coatings are typically a polyester polyol with an isocyanate. Sorry for all the science, but that chemistry allows a very durable coating. If you’re able to now modify that coating and do this interpenetrating polymer network with these additives in it, you’re able to still maintain that durability.

IRA FLATOW: Are there other kinds of specialty performance coatings already out there?

TOM KENNEDY: Again, good question. And it was in the ’90s that Spalding came out with a ball called the Aero. And that coating was very hydrophobic. And I remember getting calls from some of the consumers.

They were very upset because golfers like to mark their balls with a Sharpie. And they said, I can’t get any Sharpie to mark on this golf ball because of the coating, so anti-graffitical coating, if you will. And this coating goes the other way.

IRA FLATOW: I know that golf, being sort of a duffer myself, has a lot of rules about the equipment. Is this a legal thing to do to the golf ball?

TOM KENNEDY: Absolutely, and that’s why I mentioned the other coating that was out there for the Spalding Aero golf ball. This modification of the coating, the USGA said that was fine. The USGA and the RNA both approved of it.

That being said, I still need to talk to the ruling bodies of golf and make sure they’re OK with this coating. But it has a very small effect on what’s going on with the ball. The ball aerodynamics are still very similar, actually exactly the same.

The durability is exactly the same, and the ball still stays clean. So having this change to the coating allows this hydrophilic nature. And I don’t see that that’s a huge difference from what the current products are out there. Plus, this has been allowed in the past, where other coatings of different attributes, as I mentioned.

IRA FLATOW: Have you run your idea past any golf ball makers?

TOM KENNEDY: Well, that’s what we’re hoping to do. We’re presenting first here at the ACS meeting in San Diego, and we do have several patent-pending applications for this new science. So we’re hoping to go to them and say, hey, here’s something we think could be very helpful for both the average golfer and for the pros. And it’s something that we’d like to work with you to develop further.

IRA FLATOW: I was interested to see that there are other applications that this coating could be used for. Tell us about that.

TOM KENNEDY: Well, and I believe you’re talking about the solar cells.

IRA FLATOW: Yes, solar panels.

TOM KENNEDY: Yeah, absolutely, that can be an area for improvement. A lot of people are looking at these hydrophobic coatings, and they’re doing that because you see the water bead up, like you would when you put like hot wax on a car hood, something like that.

IRA FLATOW: Right.

TOM KENNEDY: And, intuitively, that seems to be a good thing because it keeps the surface clean. However, the problem with those coatings is that they wear over time, and dirt gets on the surface of the solar panels, which can reduce the amount of energy coming through by up to 7%. So we actually have a large array on our house, and I can see all the dirt on there during the summer.

And I’m, like, gee, I hope it rains soon, so it washes some of that off. But these hydrophilic coatings will act as a sheeting action, very similar to what you would see for getting very clean glasses in your dishwasher. So the sheeting action will allow the surface of the panels to be cleaned by rain, by dew in the morning, because the water is going to sheet out on the surface as opposed to bead up.

IRA FLATOW: Wow, wow. So how soon might we see a test use of your golf ball on TV or some other place?

TOM KENNEDY: Well, I’m hoping for later in the season. There’s a lot of development that has to go on, both from a chemical standpoint and also from working with the golf ball companies, as you mentioned. So I’d love to be able to do that with them. And, usually, that takes about six months.

So plus it has to be approved by the USGA and the RNA. So with all those logistics in place, I’m guessing around that time frame so later on in the golf season is my hope. But the phrase I’ve always heard for invention is this is something the world needs. And I think this is something the world needs because, gosh, those greens are so fast, and you see how frustrated the players get.

IRA FLATOW: I wish I were a good enough golfer that this would affect my game. So thank you, Tom, and good luck. We’ll wait to hear what happens. Check back in with us, will you?

TOM KENNEDY: I absolutely will, Ira. Thanks for checking with me, and I appreciate the interview.

IRA FLATOW: Tom Kennedy, owner of the company Chemical Innovative Solutions in Massachusetts.

Copyright © 2025 Science Friday Initiative. All rights reserved. Science Friday transcripts are produced on a tight deadline by 3Play Media. Fidelity to the original aired/published audio or video file might vary, and text might be updated or amended in the future. For the authoritative record of Science Friday’s programming, please visit the original aired/published recording. For terms of use and more information, visit our policies pages at http://www.sciencefriday.com/about/policies/

As Science Friday’s director and senior producer, Charles Bergquist channels the chaos of a live production studio into something sounding like a radio program. Favorite topics include planetary sciences, chemistry, materials, and shiny things with blinking lights.

Ira Flatow is the founder and host of Science Friday. His green thumb has revived many an office plant at death’s door.