For These Robots, Squishy Is Superior

29:48 minutes

Every time robotics company Boston Dynamics comes out with a new video promoting its dog-like, door-opening robots, internet viewers have a predictable reaction.

“People look at the dog-like things and they go, ‘Whoa, that thing is going to kill me,'” says Barry Trimmer, a neurobiologist and roboticist at Tufts University. “It looks so unnatural and intimidating, you can’t imagine that being a robot you’d want to use in your home or hospital.”

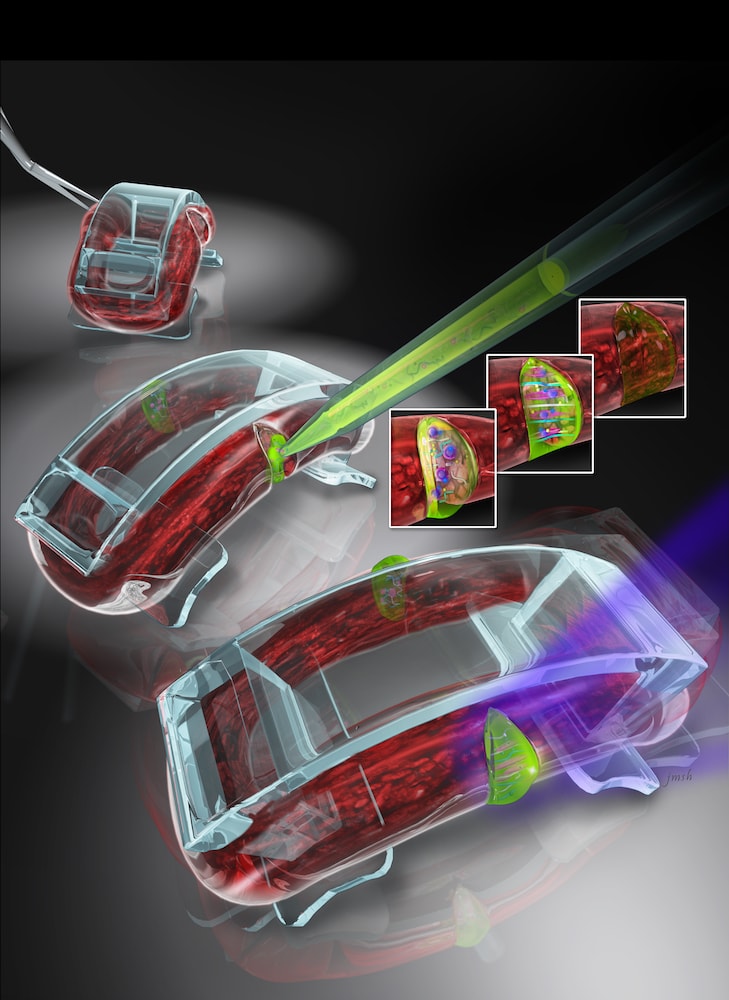

The robots Trimmer and other engineers are building are softer, squishier, and, as he imagines, friendlier—robots you might knowingly invite into your home to hang out. Instead of sporting bodies of rigid plastic and metal, biohybrid robots often consist of 3D-printed scaffolds laced with lab-grown muscles, sourced from the cells of mice, insects, and even sea slugs.

“Once you can build robots that are soft and you can control them you have access to all these materials for machines that previously we never even thought about using,” Trimmer says. Natural materials also have a unique advantage: they’re biodegradable. “You just build the thing out of protein and after you’re finished with the robot, you throw it on the compost heap and it decomposes.”

[Figure skating is physics in action. Here’s a breakdown of the physics behind those leaps and spins.]

Like regular robots, the biohybrid robots can be controlled with microcontrollers—but engineers are also building muscles controlled by neurotransmitters and light pulses. MIT engineer Ritu Raman has experimented with both types of biological machines, and has even created bio-bots that can heal themselves after an injury, and get back to work.

What kind of work might we employ bio-bots for? Raman envisions her robots could be used in biomedical applications, such as fixing damaged muscles, or aiding the constrictive movements of the throat or intestine.

Vickie Webster-Wood of Case Western Reserve University, who has experimented with the sea-slug-muscle robots, says the aqueous origins of the muscles point to underwater applications, perhaps environmental monitoring, or hunting down leaks in an oil pipeline.

In this segment, Ira is joined by Trimmer, Raman, and Webster-Wood to talk about the growing fleet of biohybrid robots.

Plus, try making your own memory wire circuit with this resource.

Ritu Raman is a mechanical engineer and postdoctoral fellow at Massachusetts Institute of Technology. She’s based in Cambridge, Massachusetts.

Vickie Webster-Wood is a postdoctoral research fellow in the Tissue Fabrication and Mechanobiology Lab at Case Western Reserve University in Cleveland, Ohio.

Barry Trimmer is Editor-in-Chief of Soft Robotics, and a professor of Biology at Tufts University in Medford, Massachusetts.

IRA FLATOW: This is Science Friday. I’m Ira Flatow. Does the name BigDog ring a bell? It’s the name of that horse-sized robot from the company Boston Dynamics. You know what I’m talking about. It’s that creepy robot that can jog and trot and climb over rubble– slip on ice and get right back up again. Maybe you’ve seen it on YouTube. It’s kind of scary.

Well, the company’s newest creation– the SpotMini– is smaller– about the size of a Rottweiler. And it can open doors by itself, and this week we watched, with some concern, a new video which the SpotMini fends off a human handler trying to interfere with the task at hand, just like a mischievous dog would.

These robots are obviously inspired by the movements and mechanics and behaviors of real four-legged creatures. But they’re made of rigid metal and plastic. Well, why not take inspiration from the whole animal? Try to recreate its muscles and its nerves to make a robot that’s partly a living thing. That’s the goal of my next guests who create so-called biohybrid robots– soft robots– squishy, flexible things that may someday be a whole new lineage in the robotic family tree, and maybe, a bit more lovable too.

Ritu Raman is a postdoctoral fellow– Ritu Raman is– I’m sorry– a fellow at Massachusetts Institute of Technology in Cambridge. Welcome back, Ritu.

RITU RAMAN: Thank you, Ira. It’s great to be back.

IRA FLATOW: Vicki Webster-Wood is a postdoctoral research fellow at Case Western Reserve University in Cleveland. Welcome, Vicki.

VICKI WEBSTER-WOOD: Hi, Ira. Thanks for having me.

IRA FLATOW: You’re welcome. Barry Trimmer is Editor-in-chief of the journal Soft Robotics and professor of biology at Tufts University. Welcome to Science Friday, Professor.

BARRY TRIMMER: Hi, Ira. Thank you very much for having me on the show.

IRA FLATOW: Ritu, let me start with you. Last time we had you on a couple of years back, the idea was, can you make artificial muscles walk? But now, I understand you’ve been able to thread neurons in there to activate the muscles more like what happens in our bodies?

RITU RAMAN: Absolutely. Yes. So we, initially, started with muscle because we thought walking is this really easy thing for people to see. But once we got the walking down, we thought, well, it’d be really nice to be able to control that walking in a new or interesting way. So we worked on controlling the bio-bots walking with light, and then, after that, we moved to adding different types of cells– neurons– where we tell the neurons to go on or off and then watch the bio-bot respond to that cue.

IRA FLATOW: So this thing is basically a robot, but it does what you tell it to do. And it’s made out of real flesh– real tissue.

RITU RAMAN: Yes. I think if you broadly define a robot as anything that senses processes and responds to a signal in real time, then a bio-bot is really something that uses biological materials to do one or all of those things.

IRA FLATOW: Now, Dr. Webster, what I understand– that you’ve also done work on integrating neurons into bio-bots’ muscle circuits. What is the advantage of doing that instead of just zapping the muscle with electricity?

VICKI WEBSTER-WOOD: Absolutely. So I work a lot with tissues from a sea slug. It’s a very robust material, and what we can do with that system is we can actually isolate whole muscle tissue along with the nerves that innervate the muscle and the clusters of neurons that feed into those nerves.

And what we’ve seen is that if you stimulate the muscle directly– electrically– the muscle fatigues very quickly. However, if you stimulate the muscle via the natural neural circuitry, whether that be via the nerve itself or by inducing natural motor patterns in the clusters of neurons, we see much better performance in the muscle when we stimulate via that natural circuitry, with better stimulation from the nerve and even better stimulation, yet, when we stimulate the neurons themselves, both in terms of the fatigue of the muscle and the output of the muscles. So by using that circuitry, we can have more robust, more powerful robots.

IRA FLATOW: So the nerve knows how to do it better is what you’re saying.

[LAUGHTER]

VICKI WEBSTER-WOOD: Essentially, yes.

IRA FLATOW: Do you have to follow your robot around squirting it with neurotransmitters, keeping it wet– keeping it alive with the liquids we all need in our bodies?

VICKI WEBSTER-WOOD: Right now, our robots are running around in petri dishes in a liquid environment that has the right salt balances and glucose to provide energy to the robot. And we are stimulating it by just putting a little drop of chemical on the clusters of neurons. In the future, we may be able to incorporate microfluidic systems that would, basically, spit out a little bit of chemical at the right time for the action we want from the robot. Or we may be able to incorporate sensory cells and actually have the robot be stimulated by external sensory cues like a chemical gradient in the liquid.

IRA FLATOW: Were you serious when you said you had little petri dishes running around? Is that literally what’s happening?

VICKI WEBSTER-WOOD: No, the robots are running around in the petri dish.

IRA FLATOW: Oh, I see then. The dishes aren’t–

VICKI WEBSTER-WOOD: Yes.

IRA FLATOW: –running around. OK.

VICKI WEBSTER-WOOD: No, no, it’s like having a little aquarium for your robot.

IRA FLATOW: Well, yeah, that’s what I was wondering– how you keep them all bathed in what they need. Dr. Trimmer, what’s the problem with regular, hardbodied robots? What advantage does real flesh or soft bodies give them over the kind of robots we’re used to?

BARRY TRIMMER: Well, I don’t want to be sounding critical of our current robots. I actually think that they are truly remarkable. And the things that you mentioned earlier on about the Boston Dynamics robots, it’s a tour de force. I mean, it truly is amazing what they’ve been able to do.

But there are many, many tasks and things that we would like to have help with that traditional hard robots aren’t particularly good at doing. If you imagine having robots in the home or the office or the hospital, you’d like them to be pretty safe. And you don’t want them just control-safe, in other words, you don’t want them to be safe as long as they’re controlled but not safe when they’re uncontrolled.

And current hard robots are control-safe. In other words, we only want to put people around them as long as they’re in control. I think, by trying to incorporate soft materials and biomaterials into robots, we can create machines that, actually, will be completely safe– intrinsically safe. So even if the control systems fail, they’re not going to do very much harm. So that’s one aspect.

I think the other one that we need to touch on is that soft materials and biomaterials let the robots operate in lots of ways that our traditional robots can’t. We can get them to change shape and size. We can get them to wiggle through a pile of debris that might have fallen and join an emergency situation and find people. We can have them work in the delicate canopy of a forest or in a field. And those sorts of things are much, much easier to imagine with a robot that’s more like a biological specimen that actually isn’t going to damage the world around it.

IRA FLATOW: Interesting. 844-724-8255 is our number– 844-724-8255. You can also send us a tweet @scifri. Ritu, is skeletal muscle also a strong building tool– more power, more force for its size– than any other types of things you could build with?

RITU RAMAN: Absolutely. So I’m actually a mechanical engineer by training, and when we think about the synthetic actuators that we have available to us and, then, compare it with what nature has evolved to do, all of its force– production, locomotion, which is skeletal muscle– I mean, it’s just phenomenal how much power it can generate from such a small size and how efficiently muscle can do it.

So when we’re thinking about designing the next generation of robots and systems, sure, we could go in and look at synthetic actuators. But if we have something that we know works better, we should absolutely go for that. Right?

IRA FLATOW: Yeah. Dr. Webster-Wood, I’ve been studying cells for many years, and I remember the first time I studied cardiac cells, I discovered that if you take a cardiac cell and you put it in a petri dish, it’ll start to beat on its own. And then, can you use that kind of action to create a mechanical device or a biohybrid robot– that sort of trait of a muscle or sort of trait of what the living flesh is?

VICKI WEBSTER-WOOD: Absolutely, and there’s some very interesting examples of these biohybrid robots that use cardiac muscle as the actuator. Like you said, when you think about cardiac muscle, you think about a heart beating spontaneously. And we do see that with the cells in the dish.

One example, recently, that actually I think is a good example of combining bio-inspiration and biohybrid robots is actually– a group under the direction of Dr. Kevin Kip Parker developed a jellyfish-inspired biohybrid robot where they actually studied the structure of the musculature in the jellyfish and reproduced that on a synthetic device by microcontact printing proteins that heart cells would like to attach to.

And then, when the heart cells attach, they spread out and follow these proteins. And so you can basically design a actuator that will self-assemble so that all the heart muscles are pulling together in one direction. And in this way, they were actually able to capture a lot of the locomotion– the similarities that they saw in the real jellyfish.

IRA FLATOW: And can you actually make them small enough, I mean, that they could go to work inside the body to do something useful?

VICKI WEBSTER-WOOD: Potentially. I think one of the great applications that a number of researchers in the field are talking about is creating very small-scale biohybrid robots, or even completely organic robots– which we like to call organobots– that you can make out of, say, biological polymers that are naturally occurring in the body. And then you could deploy the robot into either the digestive system or the vascular system and have it provide targeted drug delivery or, potentially, even deploy and provide mechanical or chemical cues to an area to, say, strengthen a vessel wall.

IRA FLATOW: I have a tweet in from Mike in Ohio who asks, if these robots are biological, can they get sick?

RITU RAMAN: I could, maybe, comment a little bit on that. One thing that we really like to talk about when we’re thinking about biological materials, we’re talking about soft materials– that’s great. But the really interesting thing about building biological materials is that they’re constantly sensing and adapting to their environments.

So that could be both negative cues, like getting sick, or as I’ve studied how we damage bio-bots and see them get hurt. But the great thing about the fact that they’re biological is that, then, they can sense that damage, or that sickness, and respond to it in a positive way. So, yes, they can get sick, but we also hope that they can get better.

IRA FLATOW: So if you put bio-robots into the water system and it detects pollution and starts getting sick from some sort of biohazard, it could say, hey, there’s something in here. Be alerted.

RITU RAMAN: Exactly.

IRA FLATOW: Yeah.

BARRY TRIMMER: And Ira, if I might add to that as well, of course, this idea of using biopolymers and living cells to make robots is what we might call green technology. These robots don’t cost a lot to make. We’re growing them instead of big factories with high temperature and lots of energy expenditure. And one of the wonderful things would be to recycle them. All these materials would be biodegradable, and you rebuild your robot from the generation that has just given up the ghost.

IRA FLATOW: All right. Hold that thought, because we’re not giving up the ghost on this topic. We’re going to take a break, and when we come right back, we’ll talk more about bio-robots after the break. Stay with us.

This is Science Friday. I’m Ira Flatow. We’re talking about biohybrid robots made of real muscles and nerves and attached to mechanical stuff with my guests Ritu Raman of MIT, Vicki Webster-Wood of Case Western Reserve, and Barry Trimmer of Tufts. Our number– 844-724-8255.

I have some interesting calls. Let’s go to the phones. Let’s go to Becky in Norman, Oklahoma. Hi Becky.

AUDIENCE: Hi. Thanks for taking my call.

IRA FLATOW: Go for it.

AUDIENCE: I have a question about the ethics of using the live issue. Is there a respect for use of that living tissue? And how is it treated in that way? Because I understand that it’s put in a pile to decompose afterwards. Could you explain–

IRA FLATOW: Good question.

AUDIENCE: –how that’s handled.

IRA FLATOW: OK. Thanks for the call. Yep.

BARRY TRIMMER: If I might try and have a stab at that one, Ira. I completely understand that using living cells of any sort is– brings a lot of ethical considerations, and we really have to think about it carefully. A lot of our biomedical needs are going to be driven by using vertebrate cells because they’re likely to be more compatible with medical issues.

But that doesn’t necessarily constrain us when we’re trying to build other types of robots. And, in fact, myself and Vicki are actually both working on non-vertebrate cells. In our case, we take cells out of insects and grow them. And I think that as long as we’re not trying to actually build and grow a brain, as such, we can have a nervous system of some sort.

But if we’re not trying to actually grow a brain or reproductive system, we’re not trying to grow animals. We’re trying to build an engineered device that is made of living cells. And I think that we can all agree there are some ethical issues we need to talk about and that needs to be dealt with. We need to, really, get on top of that before this technology starts to take off in a more commercial sense. But there are ways in which we can deal with those ethical issues, I think, with the selection of the tissues that we use to build the robots.

IRA FLATOW: Ritu, you have any– Ritu or Vicki, any comment?

VICKI WEBSTER-WOOD: Yeah, I’d like to just add to that a little bit. With the work we’re doing with invertebrates, it’s very possible that as we move this technology forward, we may be able to, essentially, farm the cells. In the real aquatic environment, the sea slugs produce these egg chains. And we may be able to actually get cells from the egg chains rather than needing to work with adult animals.

And then, also looking at the applications we’re looking at, when we’re working with these type of biohybrid robots and they’re completely biocompatible– they’re completely organic, even– if we deploy them into a sensitive ecosystem and the robots are able to perform monitoring tasks in that environment, we’ll be able to more conscientiously monitor and look after these sensitive environments.

And then, if the robot breaks down, it’s not leaching heavy metals out into the water. If a fish eats it, it’s not going to hurt the fish. And so I think there’s a balance there in our stewardship of the environment with these robots.

IRA FLATOW: Speaking of which, if the robot gets injured– let’s say a fish grabs it and it just gets away– is it able to heal itself while it’s still in the wild– Ritu?

RITU RAMAN: Absolutely. So I would say, right now where the technology is we’ve made these skeletal muscle-powered bio-bots. So they have a flexible skeleton and they have this skeletal muscle that goes around them. And every time the muscle contracts, the skeleton moves and the robot walks. So we went in and we cut the muscle with a little pair of scissors. And then the bio-bot was hurt, and it couldn’t walk anymore.

And now, if that were a traditional robotic device made of synthetic materials, that would be the end of the road. You just have to scrap that robot and start over. But we thought, OK, what if I could just go in and put some sort of glue, and that glue– we’ve really optimized the concentration and composition of that. We said, OK, maybe it needs a few cells. Maybe it needs some proteins and growth factors.

We took inspiration from how muscle heals inside the body, and we tried to recreate that on the bot. And what we saw is that because of these biological materials and cues, the bio-bot would heal and, within two days, start walking again, producing the same kinds of forces and walking at the same speeds as before.

So I wouldn’t really call that self-healing, quite yet. I think it’s healing. But if at a later date we start thinking about can we incorporate vascular network or someplace where the bio-bot can store this healing glue in case it gets hurt, and then release it once it’s hurt, then you could call that sort of behavior closer to self-healing.

IRA FLATOW: I guess you had to experiment to come up with this poultice, so to speak.

RITU RAMAN: Mm-hmm.

IRA FLATOW: Help the– help the–

RITU RAMAN: Yeah, it was a long process. But it was an experiment, but, also, it was kind of easy because nature had already figured out how to do the healing. I just had to understand it and try to recreate it in the lab.

IRA FLATOW: We have lots of tweets coming in– lots of phone calls. Let me go to this interesting tweet that– I was thinking about this a while back– from Shawn, who says, “Could bio-bots be used to replace damaged muscles and nerves in the human body?”

RITU RAMAN: Absolutely. I mean, I think that’s something that we’re trying to do, right now, where there’s an established field of tissue engineering where you think about creating new tissues or organs and replacing diseased or damaged tissue or organs in the body. And bio-bots have kind of been evolving in parallel, but a lot of the lessons that we’ve been learning about how to make muscle or how to make neurons could be applied back in medicine as well.

IRA FLATOW: Can you give me a specific where that might show up first, for example?

RITU RAMAN: So one example could be any sort of disease where you have some sort of muscle degeneration, or perhaps, like a volumetric muscle loss injury– something where it’s so much of the muscle that the body can’t heal itself. Could we, then, go in and put some of our tissue-engineered muscle in place and see a person be able to recover function of that limb?

IRA FLATOW: Does somebody want to jump in there?

VICKI WEBSTER-WOOD: Yeah, I mean, I’d just like to add on that, too, that the robots really provide us with a interesting laboratory test platform to develop all of these techniques to, then, apply to actual clinical applications. Oftentimes you hear about these “lab on a chip” type systems, and that’s where, usually, people are growing tissues in a single layer on a chip. But if we want to develop techniques for– as Rita said– replacing, say, volumetric muscle loss injuries, then we really want to be testing those techniques in a system where we’ve got a bulk tissue that’s actually performing a task like it would in the body.

IRA FLATOW: Yeah, well, could you actually make prosthetics out of these, you know?

VICKI WEBSTER-WOOD: I like to think so, yeah. One of my long-term goals is definitely to pursue this idea of biohybrid prosthetics, where, in the short term, that may be replacing a chunk of muscle in a volumetric muscle loss injury. But in the long term, we may be actually able to consider building large-scale functional tissues into the more traditional prosthetic shells that people are familiar with in order to give patients back a better organic feel to their use of their limbs.

IRA FLATOW: I have a call from Andre in Pittsburgh. Hi, welcome to Science Friday.

AUDIENCE: Hi, Ira. Thank you. Love the show. Thanks for making science so fun and interesting every Friday.

IRA FLATOW: You’re welcome.

AUDIENCE: I have a question. So I run a facility in Pittsburgh that does hands-on biotech experimentation with kids and youth. And this sounds like this would be a really awesome experiment to implement in the lab. So I’m calling to find out how feasible do you think it would be to do a small-scale experiment like this to illustrate this to youth around the city, and to get them really excited about these micro bio-bots.

IRA FLATOW: Is there a do-ti-yourself home kit, yet, to make–

RITU RAMAN: I actually would love to comment on this.

IRA FLATOW: Yes, go ahead.

RITU RAMAN: So that was my idea. A couple of years ago, when I was on the show, and we got a lot of feedback, there was a lot of people saying, I want to build my own bio-bot. So I started thinking about how to make a kit to do that. And I actually started my own undergraduate class at the University of Illinois– where I was at the time, and that’s currently in its fourth year– where bioengineering undergraduates who are used to working with cells start to learn how to design and build and test their own bio-bots.

So now that we have that in place, I think it would be great to think about bringing it to an even younger audience, where, maybe, you’re not designing and building everything from scratch, but we give you a bio-bot, we ship it out to you, and maybe you can assemble a couple of parts together, and you can see how it moves or walks around. Really, the only requirements there would be that you have a warm environment and a petri dish with that sugar water that the bio-bots need to walk. So that would be great.

IRA FLATOW: You actually touched on my next question, and that is– let me send this to Barry. Are the bio-bots also an opportunity to think about different methods of fueling our machines? Well, you know, we run on sugar and fat, but the robots– could they metabolize food for their energy instead of burning oil or having lithium-ion batteries?

BARRY TRIMMER: I think, Ira, that’s, really, one of the huge advantages of trying to use a biologically-based actuator instead of the traditional engineered motors. Right now, the energy density of lithium-ion batteries is pretty good, but it’s nowhere near as good as gasoline or fat. And I don’t think you’d want to have robots working around the home that are powered by gasoline engines.

When you think about it, people sitting in a lecture hall are sitting there, and they’re just casually burning their fats and sugar fuels with no danger to people around them. So you can imagine that a muscle-powered robot– and we’re talking now about something that’s quite large– it’s not just a little tiny micro-bot– but a muscle-powered robot would, essentially, be the same as we are in that we would provide it with a sugar infusion, or maybe it’s got its own onboard fat.

And if we designed the system well, it simply uses that as its fuel source. And that means that it can operate for days and days and days without being refueled. And, of course, that isn’t possible with most current untethered robots. They really run through their batteries pretty quickly. So I think, yes, it’s a great vision. It also gets us away from– as Vickie and Ritu already said that– it gets us away from the toxicity and dangers of some of our current technology.

IRA FLATOW: If you have a robot that has a certain percentage– a large percentage of it made out of flesh, muscle, whatever, doesn’t it also do two things? Doesn’t it, first, humanize a robot and make it be less threatening to people who figure, well, if it’s these giant metallic robots go out of control, I can’t do anything, but this one seems kind of vulnerable if I know where to hit it with a stick. You know?

BARRY TRIMMER: Well, I think it’s absolutely true that one of the advantages, perhaps, of a soft robotic technology using biological materials is that we will have a different relationship with the robot. There are lots and lots of interesting social questions about that– about how that would be implemented, but, as I mentioned earlier, my goal– even though ironically, I’m a neurobiologist by training, and you’d think I would be in favor of growing brains.

I don’t think that we need to put brains into these robots. I think they will have biological components. They will have muscle. But I think we’d be best advised to be controlling them with microcontrollers and computer chips, certainly, in the near future. That’s the way it’s got to be. So they would be humanized, but not human.

IRA FLATOW: This is Science Friday from PRI– Public Radio International. Talking with three real humans on the line– Ritu Raman of MIT, Vickie Webster-Wood of Case Western, and Barry Trimmer of Tufts. Where do you see this, Ritu? Where do you see, in the macro world, how this is all going to play out?

RITU RAMAN: So I think touching on this point of humanization, I want to emphasize again, I think, our goal is not really to create any sort of living machine or robot. The real goal is to say, for thousands of years we’ve been building with these materials like metal and wood, and they aren’t sensing or adapting to their environment in any way. So when we have a dynamic problem, we don’t have these dynamic solutions. We have these very static solutions that we then have to go in and change every few minutes or hours or weeks.

And so what I think, and what I hope other people in the field think, is how can we just expand the set of materials or the tools that engineers have to work with so that they also include these responsive, biological materials? So when you’re building a machine to address a problem, not only do you have access to wood and metal and ceramics, but you also have access to these kinds of biological materials.

So that’s how I think I would love to see people using these sorts of just an additional thing that they have in their toolkits. So if they’re thinking about building a robot, OK, maybe I need an actuator. I was going to use the synthetic actuator, but instead I’m going to use this muscle instead.

IRA FLATOW: Yeah, because nature has figured that out already. Right?

RITU RAMAN: Mm-hmm, exactly.

IRA FLATOW: It’s come up with a really good device for you. Why not use it?

RITU RAMAN: Mm-hmm.

BARRY TRIMMER: That and that’s very true, and not only that, it’s self-assembles. It starts off with a cell and a bunch of chemicals, and it constructs the entire piece of tissue with all of its incredible complexity without us having to intervene. And I think the idea of growing robots without actually fabricating them is a very, very attractive one.

IRA FLATOW: That’s an interesting way that you put it– growing them. How large, theoretically, could you grow the muscle, the tissue, or whatever you need in the robot, and what are the limits, practically speaking, Barry, on this?

BARRY TRIMMER: I think that we’re still at very early stages right now, which is why we’re all working with relatively small amounts of tissue. There are challenges, particularly with using vertebrate tissue where we need to have the vasculature. We need to control the environment of the cells quite carefully. Little less of a problem with that when we’re using insect tissues because they’re used to living in an open circulatory system, and so they tend to be much, much tougher.

So some of the limits on how big they get depends on how well we can construct those scaffolds on which the muscle needs to grow and then survive. In my opinion, if we learn enough about how the size and the shape and the nature of a tissue is actually developed into a living animal in the first place, then we should be able to engineer it. So when you think about it, we have muscles in insects as small as– less than a millimeter, and we have muscles in whales as big as cars. And so tissue knows how to do it. We don’t know how to do it yet, but the limit is that we don’t know how to do it, and we’re trying to find that out.

IRA FLATOW: OK. No better way to end this discussion on that note. Barry Trimmer is Editor-in-chief of the journal Soft Robotics– professor of biology at Tufts in Massachusetts. Vicki Webster-Wood– postdoctoral research fellow at Case Western Reserve in Ohio in Cleveland. And Ritu Raman is postdoctoral fellow at MIT in Cambridge, Massachusetts. Thank you all for joining us this hour.

RITU RAMAN: Thank you for having me.

VICKI WEBSTER-WOOD: Thank you.

IRA FLATOW: And we have photos–

BARRY TRIMMER: Thank you.

IRA FLATOW: –and videos of the bots that they were talking about on our site at sciencefriday.com/biobot.

Christopher Intagliata was Science Friday’s senior producer. He once served as a prop in an optical illusion and speaks passable Ira Flatowese.